THE BLUE DOT BENEFITS

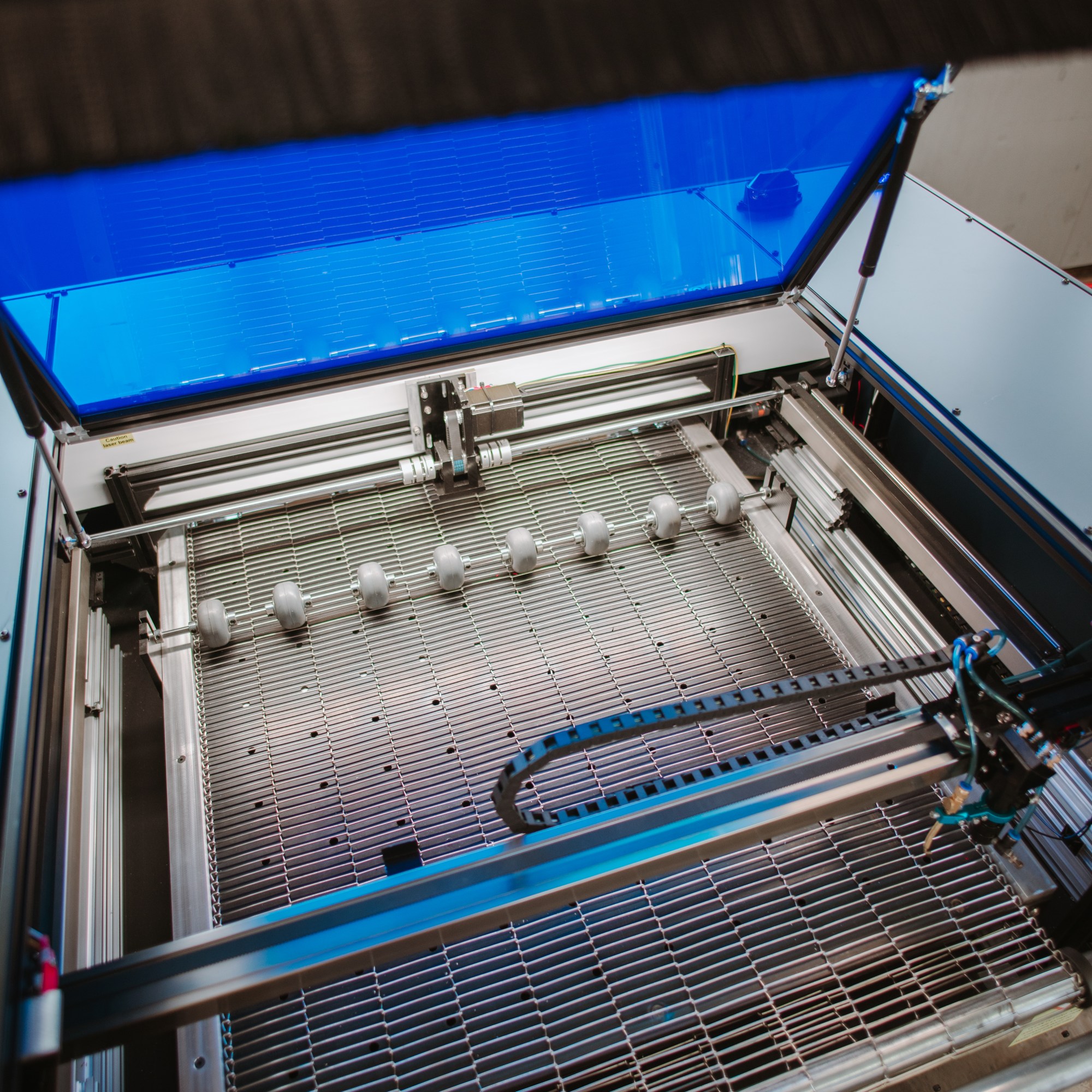

CUTTING FIELD

30″ wide x unlimited length for roll-fed materials.

30″ wide x 18″ deep for sheet-based materials (with pass-through capabilities for longer and rigid materials).

PRECISE & QUICK CUTS

Proprietary technology holds the material as flat as possible in the level cutting field; an adjustable lens height between the material that is being processed and the precise “flying optics“ of the high speed X-Y gantries create quick and clean cuts in flexible materials.

EASY LOAD ROLL MATERIALS

Adjust the auto-feed system to your particular material width for heightened accuracy. Add our custom re-wind stands or outfeed stacking stations to increase job processing ease and speed.

SIMPLE SOFTWARE

Each laser machine is equipped with laserCAD software. You can design any part or shape for cutting within this program or import any .dxf file you prefer.

BUILT IN THE USA

Engineer support when you want it and replacement parts when you need it. Our machines are designed, built, and maintained from our South Carolina based laser lab.

CHILLER, AIR & SMOKE

We’ve thought through the needed accessories and integrations so that you don’t have to. Each laser includes a chiller, highly effective internal air assist & smoke collection system.

5

LASER MACHINE MODELS

12

MILLION ITEMS FABRICATED

15

YEARS OF EXPERIENCE

We specialize in manufacturing cost-effective laser machinery for cutting non-metallic materials including abrasive papers, films, and cloth. Materials in roll form are automatically fed into the cutting area for improved efficiency with our reel to reel auto-feed system.

We own flat. That’s part of the magic of cutting thin substrates with lasers. Our laser X-Y gantry’s are installed to make sure that all four corners of the laser cutting field are at the same height above our conveyor material feed platform. The integrated vacuum powered material positioning system ensures that the material that is fed into the cutting field remains flat. This gives you a consistent cut through the entire laser cutting field and offers faster cutting speeds.

Our technology has been in use and refined for more than 10 years for our in-house fabrication operation. When we couldn’t find the laser cutter we wanted at the price point we needed – we started building laser cutting machines from the ground up.

A single head Blue Dot Laser Manufacturing system starts at $25,000 with increased customizations ranging up to $65,000.

“ANY SUFFICIENTLY ADVANCED TECHNOLOGY IS INDISTINGUISHABLE FROM MAGIC.”

– Arthur C. Clarke